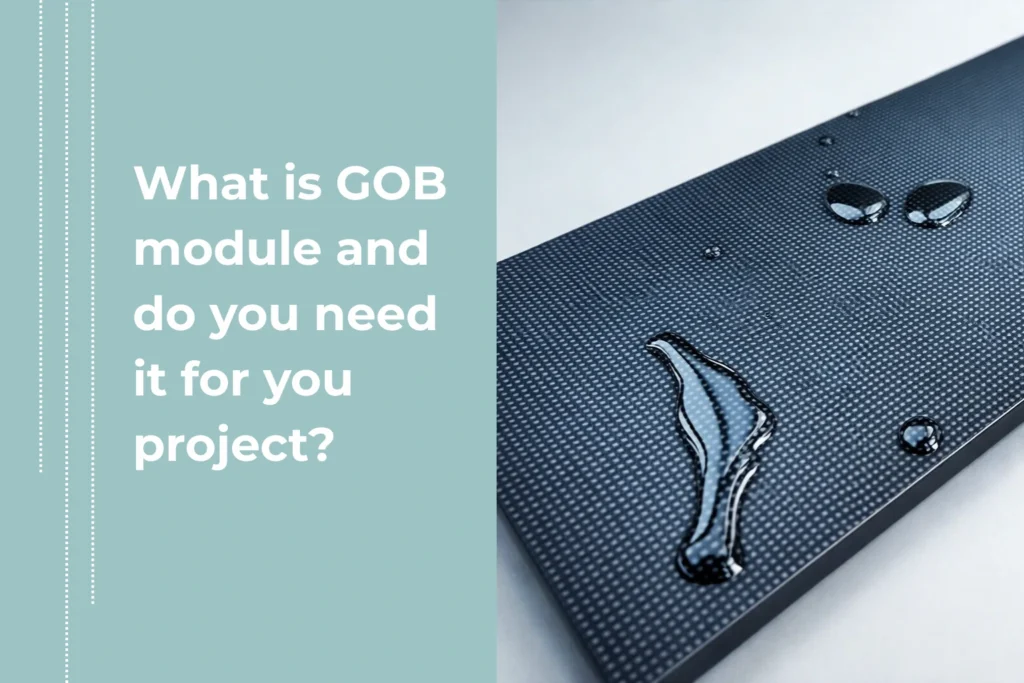

What Is GOB LED Technology?

GOB stands for Glue-On-Board. Essentially, it means that a transparent epoxy resin is applied over the LED module’s surface, protecting the tiny LED chips underneath. This glue-like layer seals the LEDs against dust, moisture, and impact — things that can easily damage traditional LED modules. From my experience, this coating not only shields the LEDs but also helps improve how the display looks. It smooths out the light output, reducing glare and making the colors more consistent, which is especially important when you’re setting up screens that people view up close. GOB is often compared to COB (Chip-On-Board) technology, which integrates LED chips directly on the circuit board. While COB offers very high resolution, GOB works by enhancing SMD (Surface Mounted Device) modules with this protective glue layer, striking a balance between durability and visual quality.How Do GOB LED Modules Work?

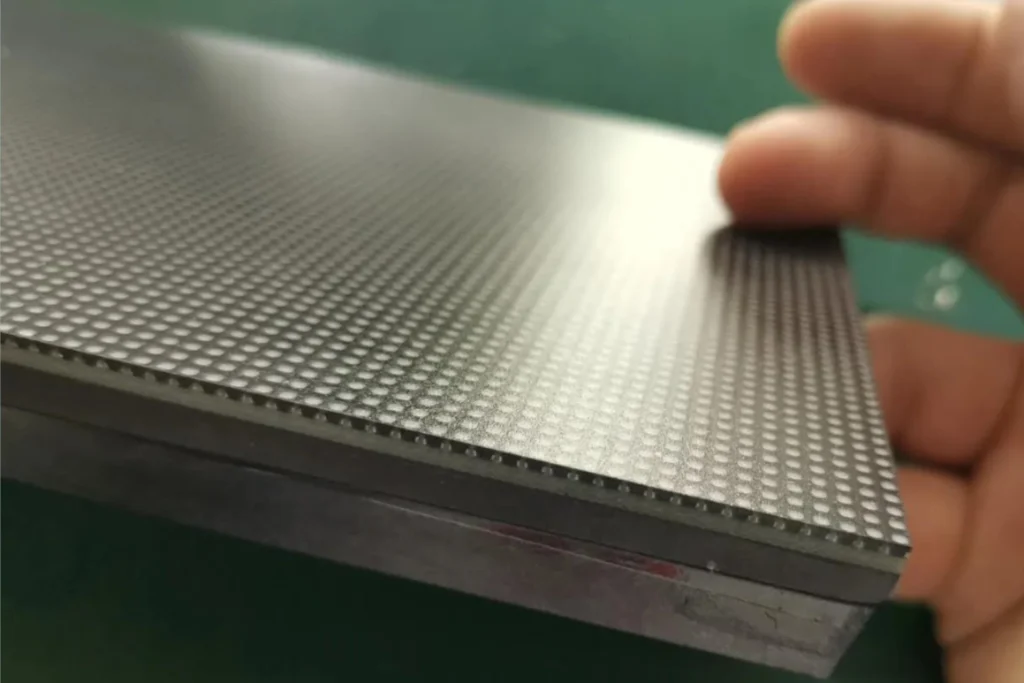

When I’m on site installing or servicing displays, I often explain the process like this:- LED Placement: The module starts as a standard SMD board where LED beads are mounted on the PCB.

- Glue Application: Then, a special epoxy resin is applied over the whole surface, carefully covering every LED bead.

- Curing: This glue is cured, usually with heat or UV light, hardening it into a clear, solid protective layer.

- Quality Check: Finally, the finished module is inspected for clarity, uniformity, and electrical function.

Why Are GOB LED Modules So Popular in 2025?

Working closely with customers across Canada, I’ve noticed several key reasons for GOB’s rising popularity:Durability That Lasts

The epoxy coating makes GOB modules highly resistant to water, dust, and physical shocks. This ruggedness is essential for installations exposed to harsh conditions — like outdoor signage during tough Canadian winters or rental screens that get packed and moved frequently.Stunning Visuals

Thanks to the resin filling the gaps, GOB modules deliver smooth, vibrant images with less glare. For venues that want crisp visuals without harsh reflections, this makes a huge difference.Efficient Heat Management

Although the glue layer sounds like it could trap heat, it’s actually thermally conductive. This helps the modules run cooler and maintain brightness and color stability over long hours.Lower Maintenance

With the LEDs sealed under the epoxy, dust and dirt don’t accumulate easily, meaning less cleaning and fewer repairs. This reliability saves time and money — especially important when managing large led wall panels or complex video walls.

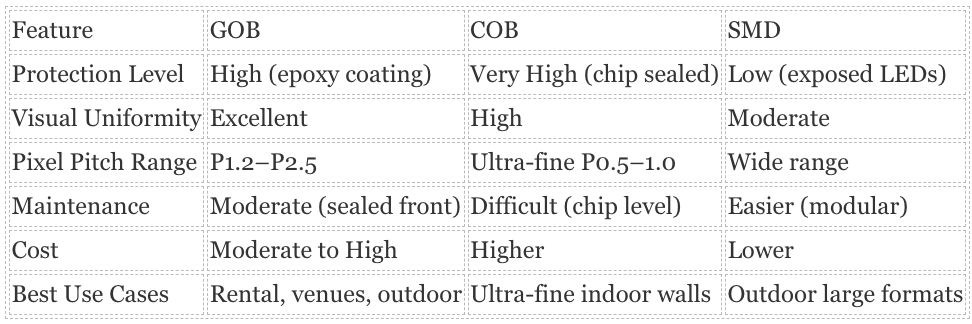

Comparing GOB with COB and SMD

Here’s a quick comparison I often share with clients deciding on technology:

GOB fits perfectly for many mid-range pixel pitch applications — offering a solid balance between durability and image quality.

Real-World Uses I’ve Seen

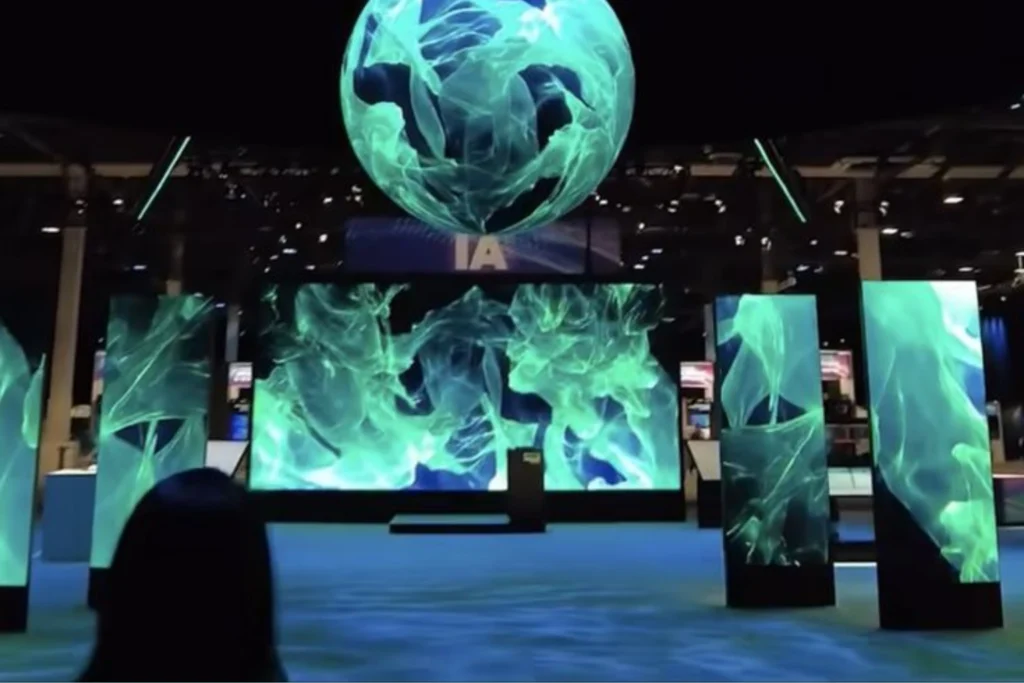

Over the past few years, I’ve installed GOB modules in all kinds of environments:- Churches: The smooth surface and protection make GOB ideal for led screens for venues where people gather and interact closely.

- Rental Events: Their shock resistance and dustproof qualities make them reliable for rental video walls that travel.

- Retail Displays: Window signage and storefronts benefit from GOB’s weather resistance and visual clarity.

- Transit and Airports: High-traffic areas where durability and consistent image quality are essential.

Video Wall Cost Considerations

You might be wondering about video wall cost when using GOB modules. While these modules can be a bit pricier upfront compared to standard SMD, the durability and lower maintenance often lead to better long-term value. For many clients, especially in rental or high-use environments, the overall savings on repairs and downtime more than justify the initial investment.Are There Any Downsides?

No technology is perfect, and GOB has some trade-offs:- The epoxy layer can slightly reduce brightness compared to uncovered LEDs, but in most practical situations, this is hardly noticeable.

- The production process is a bit longer, which can affect lead times.

- Repairing individual LEDs requires care to avoid damaging the protective layer.

Looking Ahead: The Future of GOB LED Modules

From what I see, GOB technology isn’t going away anytime soon. It’s become a trusted choice for many Canadian LED projects because of its unique combination of toughness, visual quality, and cost-efficiency. And as technologies like MiniLED and MicroLED evolve, I expect we’ll see even more hybrid solutions that incorporate GOB-style protection.